Feature

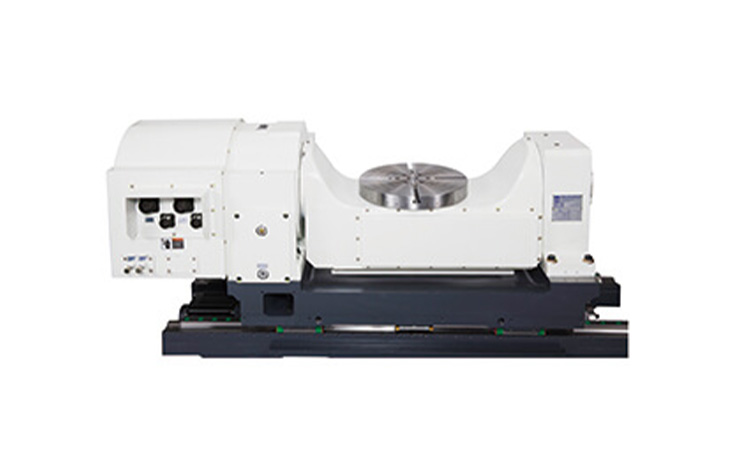

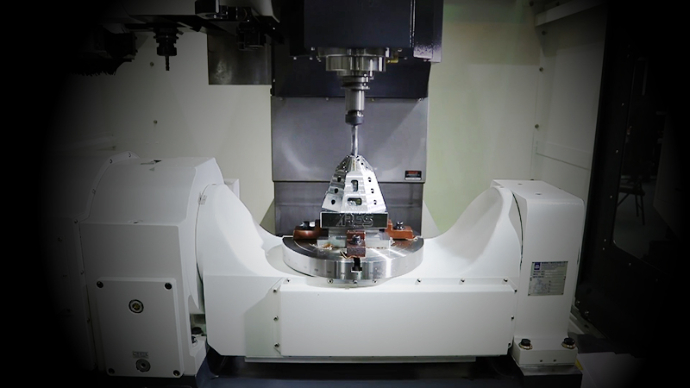

5-Axis Machining Capability and Precision

Use this snippet to build various types of components that feature a left- or right-aligned image alongside textual content.

Duplicate the element to create a list that fits your needs.

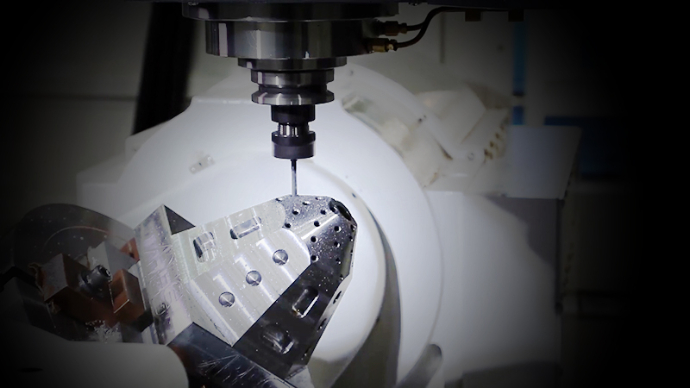

Optimal Cutting Angles and Superior Surface Finish

Speakers from all over the world will join our experts to give inspiring talks on various topics.

Stay on top of the latest business management trends & technologies

Flexible Production for High-Mix, Low-Volume Manufacturing

Use this component for creating a list of featured elements to which you want to bring attention.

Advantages

The utilization of A5X404 5 axis CNC vertical machining centers yields several cost-saving benefits

Extended Tool Life

Improved tools life reduces the frequency of tools replacements.

Enhanced Accuracy, Less Waste

Enhanced accuracy minimizes the risk of costly mistakes or material wastage.

Optimized Floor Space & Utilization

Reduce the floor space requirements, increase flexibility and spindle usage.

Lower Fixture & Inventory Costs

Decrease the need for expensive fixtures, and lower the overall inventory investment.

ARES A5X404 5 axis VMC machine centers are frequently used in sectors like aerospace, automotive, medical device manufacturing and hydraulic systems that call for intricate and exact machining. A maker can produce intricate parts and components with high precision and accuracy using a 5 axis vertical machining center.

Specifications

| Unit | A5X404 | |

| Table Size |

mm | Ø320 mm |

| Max. Table Load |

kgf | 75 |

| Max. Workpiece Dimennsion ( Ø × height ) |

mm | Ø448 × 250 |

| Min. Indexing Precision of C Axis Rotary |

degree | 0.001 |

| Slope Angle of A Axis | degree | +120 / - 40 |

| Cumulative Indexing Precision of A,C Axis | sec | 45 / 15 |

| A,C Axis Repeatability Accuracy | sec | 8 / 6 |

| Max. Speeds for A, C Axis | rpm | 13.3 / 22.2 |

| X, Y, Z Axis Travel | mm | 400 × 500 × 450 |

| 3 Axes Rapid Traverse | m/min | 48 / 48 / 48 |

| 3 Axes Bidirectional Accuracy of Positioning | mm | VDI 3441 |

| 3 Axes Bidirectional Repeatability of Positioning | mm | VDI 3441 |

| Spindle Speeds | rpm | 8,000 |

| Spindle Taper | BT40 | |

| Pull Stud | MAS 403 P40T-1 ( 45° ) | |

| Spindle Driving | Direct-Drive | |

| Spindle Nose to Table | mm | 40 ~ 490 |

| Spindle Center to Z Path | mm | 570 |

|

Spindle Motor |

|

|

| Mitsubishi |

kw | 7.5 / 5.5 |

| Fanuc |

kw | 7.5 / 5.5 |

|

Siemens |

kw | 7.0 |

| X Drive Motor | ||

| Mitsubishi | kw | 1.5 |

| Fanuc | kw | 1.6 |

| Siemens | kw | 2.3 |

| Y Drive Motor | ||

| Mitsubishi | kw | 2.2 |

| Fanuc | kw | 2.7 |

| Siemens | kw | 2.3 |

| Z Drive Motor | ||

| Mitsubishi | kw | 3.0 |

| Fanuc | kw | 3.0 |

| Siemens | kw | 3.3 |

| A Drive Motor | ||

| Mitsubishi | kw | 3.5 |

| Fanuc | kw | 4.0 |

| Siemens | kw | 3.3 |

| C Drive Motor | ||

| Mitsubishi | kw | 1.5 |

| Fanuc | kw | 1.6 |

| Siemens | kw | 2.3 |

| Tools Capacity | tools | 24+1 |

| Max. Tool Weight | kg | 5 |

| Max. Tool Length | mm | 250 |

| Max. Tool Diameter ( Alternate Pocket Empty ) | mm | 80 (120) |

| ATC Time ( T-T ) | sec | 2.4 |

| Tool Change Type | Arm Type | |

| Tank Volume | L | 260 |

| Coolant Pump Rate | W | 600 × 2 pcs |

| Flow Rate | L/min | 136 |

| Chip Flush Type | Flushing Type | |

| Auto. Chip Conveyor | OP | |

| Net Weight | kg | 4300 |

| Floor Space | mm | 2170 × 3032 × 2657 |

- Tool change time supplied with Mitsubishi controller and standard 60Hz power. For electrical requirements other than this standard, please contact one of our personnel.

- The company reserves the right to modify the specifications / design, subject to change without further notice.

- Actual specifications, based on order content.

Video

A5X404

5 Axis CNC Vertical Tapping Machining Center