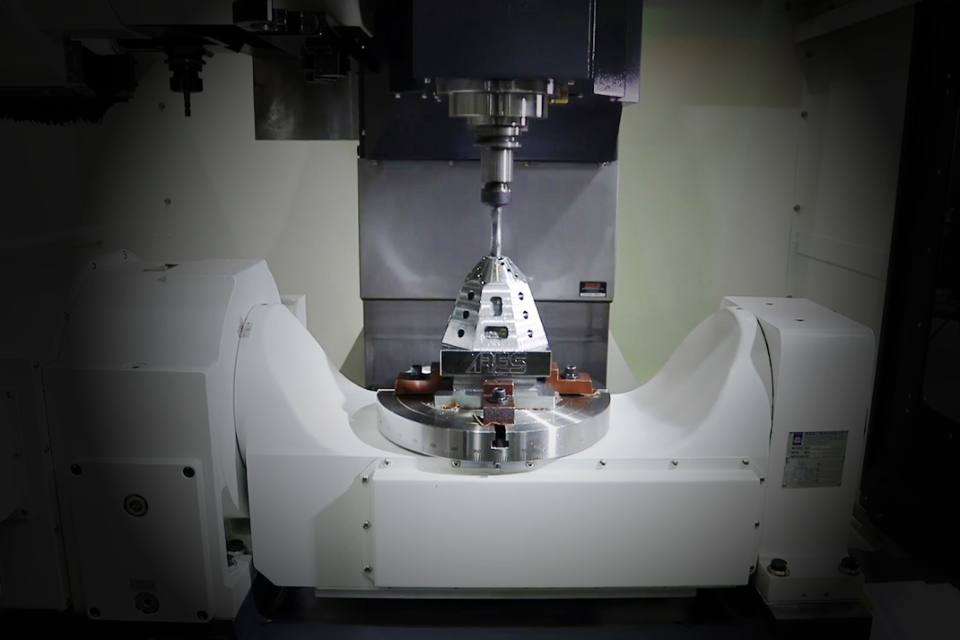

CNC Horizontal Machining Center

What is a CNC Horizontal Machining Center?

CNC horizontal machining center also known as CNC HMC, its main characteristic lies in its horizontal spindle parallel to the ground which can manage to mill metal workpieces with high precision. Besides, due to its horizontal spindle design, the metal chips would easily fall away from the workpiece instead of being stuck in the workpiece or cutters.

The primary function of a CNC HMC is often to mill grooves and slots. This machine may also employ rotary cutters to shape the metal workpiece.

Advantages of CNC Horizontal Machining Center

- H Series CNC horizontal machining center is designed to streamline setups, have an intuitive interface and automated features to reduce the complexity of setup processes, minimize the risk of errors and enhance productivity allowing less experienced operators to handle high-value-added tasks with ease.

- The design of the CNC horizontal machining center equipped with a chip conveyor device ensures that chips are swiftly transported outside the machine eliminating the need for manual chip removal, saving time and labor costs. Additionally, it mitigates the hazards associated with chip accumulation during cutting cycles, promoting a safer working environment.

- By effectively managing chip removal, the CNC horizontal machining center minimizes the likelihood of chips being re-cut resulting in superior surface finishing and enhanced accuracy on the workpiece. Furthermore, it extends the lifespan of cutting tools by reducing the wear and tear caused by chip re-cutting, leading to cost savings on tooling.

- The rotary B-axis in the CNC horizontal machining center allows for the machining of a workpiece on three sides in one cycle. This capability ensures better machining accuracy within the same cycle, reducing the need for repositioning and secondary operations. The precise control of the B-axis contributes to higher quality outputs and consistency in production.

- The CNC horizontal machining center features dual working station tables and an automatic pallet changing system (APC). This setup allows for continuous, non-stop operations, significantly raising machining efficiency. While one workpiece is being machined, another can be set up on the alternate station, minimizing downtime and maximizing throughput.

The Applications of a Horizontal CNC Machining Center

Ares Seiki has many years of experience to produce outstanding H-series machines with high speed, high accuracy, high efficiency. Because the competent and skilled capability, they can be well applicated in the wide range of industries, including:

- Auto parts industry.

- Bath-ware industry.

- 3C products like computer, communication, and consumer electronics manufacturing industry.

- Aviation industry.

|

|

|

|

|

|

|

|