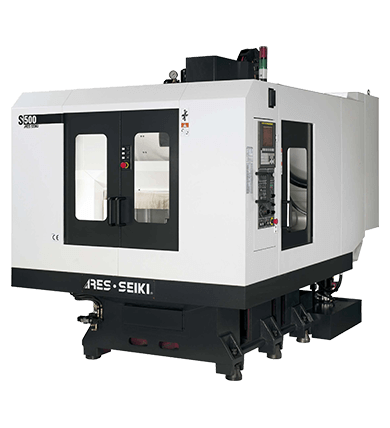

PRODUCTS

Double Stations Tapping Machining Center

What is a Double Work Stations CNC Tapping/Machining Center?

A CNC double work stations CNC tapping/machining center is a computer numerical controlled machine for drilling, tapping, milling operations, featuring high speed and high precision. With its special design of full-travel column and high-speed swing table (APC: Auto. Pallet Change), it can provide double work stations by dividing and rotating the main working table. While the interior work station is under machining raw workpieces, operator can unload the finished workpieces and reload new raw workpieces on the exterior working station at the same time. Therefore, it can eliminate workpiece changing time to offer non-stop machining operations and increase production efficiency. Furthermore, the swing table positioning mechanism can rotate smoothly without lifting up/down motions which will achieve higher reliability and excellent machining accuracy.

The Advantage of a Double Work Stations CNC Tapping/Machining Center

- Can raise machining efficiency with the double work stations design and non-stop operations.

- Can simplify pallet changing by pushing a button or commanding from CNC controller.

- Can minimize human intervention and errors.

- Can let one operator to take care of more machines during a longer period of machining cycle time on each machine.

- Can adopt manufacturing method of “high-mix low-volume” or “high-volume low-mix“.

- Can achieve faster “ROI: return on investment”.

- Can let each side of work station be equipped with one set of CNC rotary table or one set of hydraulic oil system (pneumatic) preparation for auto. fixture. This CNC rotary table or preparation is optional accessory.

The Applications of a Double Work Stations CNC Tapping/Machining Center

Ares Seiki assures that those S-series machines are quality-guaranteed. With the versatile capacity, they can be applicated in the wide range of industries, including:

- Auto parts industry.

- Bath-ware industry.

- 3C products like computer, communication, and consumer electronics manufacturing industry.